Mükemmel Sensörler

OPTIMAL DISTANCE MEASUREMENT

IN AUTOMATION

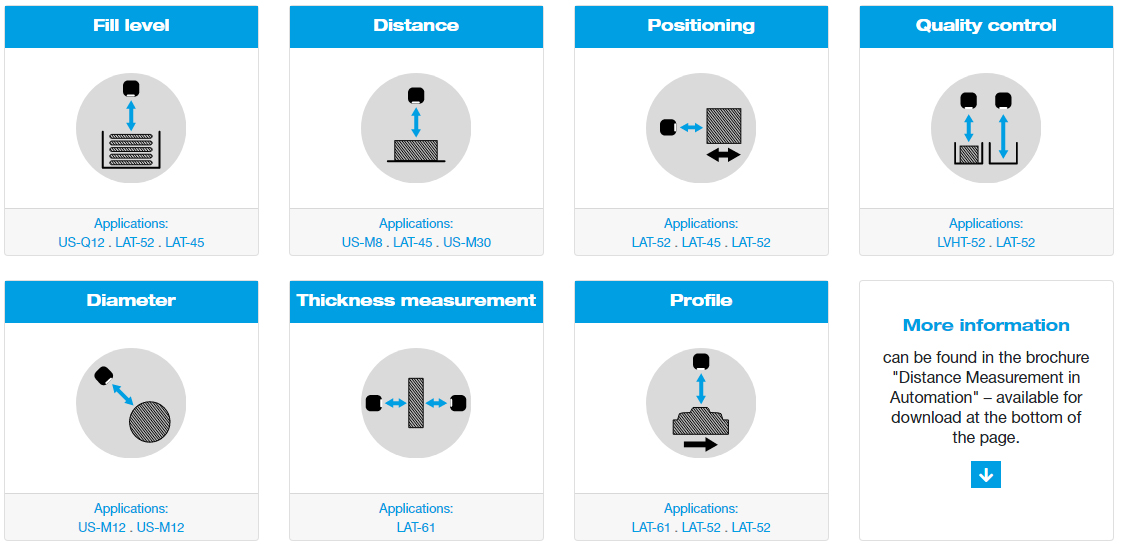

In automation, there are the most diverse application scenarios:

from measurements of fill level, object positioning, to quality control. The diverse requirements, e.g. in relation to the object surface quality or the necessary precision, result from the specific application task.High resolutions, measurements on shiny or dark objects, long ranges and high ambient light immunity – the selection of the appropriate sensor plays a decisive role here. di-soric offers the perfect sensors for contactless distance measurement for these applications in automation.

For us,

optimal distance measurement in automation

means solving the most diverse applications with as few products as possible.

di-soric’s portfolio includes various product series of optical distance sensors and ultrasonic sensors that are designed for contactless distance measurement. Our sensors impress with their innovative IO-Link functions, various sizes and strong performance characteristics in all technologies.

The implemented, innovative IO-Link functions make certain measuring tasks, such as thickness measurement or the avoidance of mutual influencing of several sensors, possible in one application in the first place.

Optical distance sensors

LAT-52 Compact

- 30 – 500 mm

- For precise distance measurement

- Universal through 3 measuring ranges

- Sensor modes, filters for optimal measuring results

- Operation using keys or via IO-Link

LVHT-52 Compact

- 50 – 500 mm

- For precise distance detection

- Compact, large measuring range

- Foreground and background suppression

- Operation using keys or via IO-Link

LAT-61 Precise

- 26 – 180 mm

- For highly precise, quick measurements

- Resolution in the micrometer range

- Up to 5,000 measurements per second

- Operation with keys and displays

LAT-45 Long Range

- 200 – 10 000 mm

- Can be used anywhere

- Ideal for dark surfaces

- High ambient light immunity

- Operation with keys, using a display or via IO-Link

Measuring ultrasonic sensors

US-M12, US-M18, US-M30, US-Q12

US-M8

SOLUTIONS

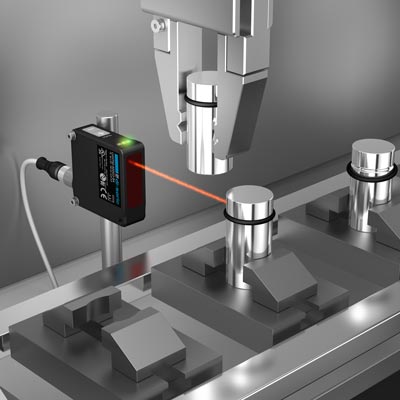

ASSEMBLY AND HANDLING TECHNOLOGY

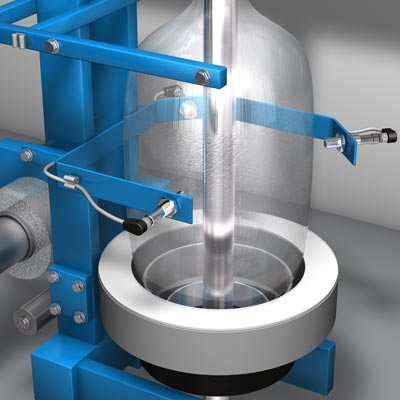

In assembly machines, individual parts are supplied, assembled and joined in an automated fashion. Each processing step is monitored. Our sensors ensure the measurement of distances in the mm or µm range, control fill levels and positioning processes, monitor size accuracy and the presence of objects. In this way, di-soric makes its contribution to the assembly of components and in the production of new products in the electronics, medical or automotive industries.Height control in containers

with step feeders

Ultrasonic sensor

US Q12 M 400 XP G3-T4

Positioning of a linear axis in pressing processes

<Optical distance sensor

LAT52-80IU-B5

Presence check for

O-ring

Optical distance sensor

LVHT52-500G3-B4

Measuring of assembled plug

contacts

Optical distance sensor

LAT 61 K 30/8 IUPN

SOLUTIONS

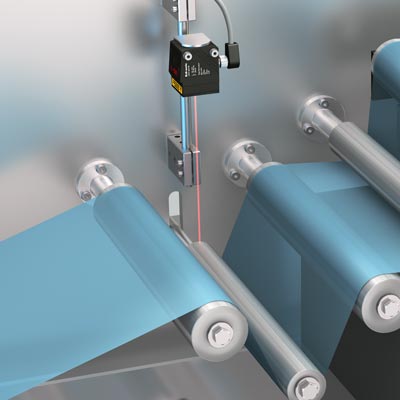

PACKAGING

The packaging industry requires sensors and sensor systems which are tailored to complex, frequently changing tasks. Distance sensors from di-soric are used for controlling manufacturing processes, the monitoring of the actual packaging processes and also for quality control of the manufactured products.Measurement of roll diameter for unwinding control

Ultrasonic sensor

US 12 M 400 IU B4

Loop control with label printing machines

Optical distance sensor

LAT45-10MIU-B5

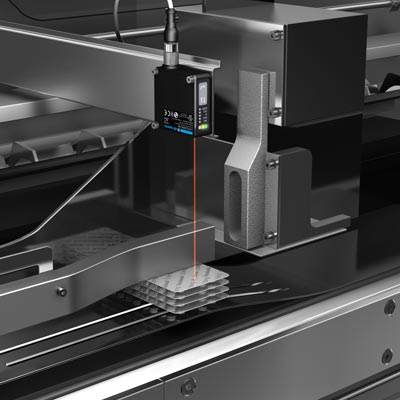

Stack control for blisters in cartoning machines

Optical distance sensor

LAT52-200IU-B5

Closure control for filling and sealing machines

Optical distance sensor

LAT52-80IU-B5

SOLUTIONS

ROBOTICS

Modern industrial robots require not only cameras as eyes, but precise sensors for detecting distances are also fundamental. Our distance sensors with laser or ultrasonic technology are predestined for sensor-guided movements in the mm and sub-mm range and therefore make control of fusion and assembly processes possible.Detection of objects in a gripper

Ultrasonic sensor

US 08 M 100 G3-T4

Distance regulation in the adhesion process

Optical distance sensor

LAT52-200IU-B5

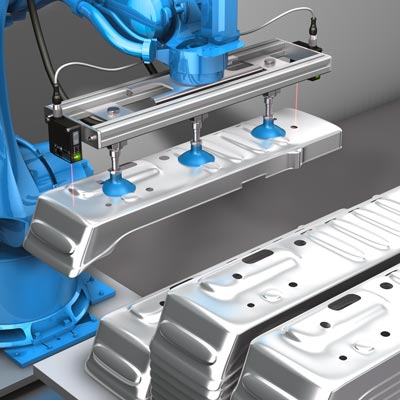

Distance measurement in the gripper

Optical distance sensor

LAT52-500IU-B5

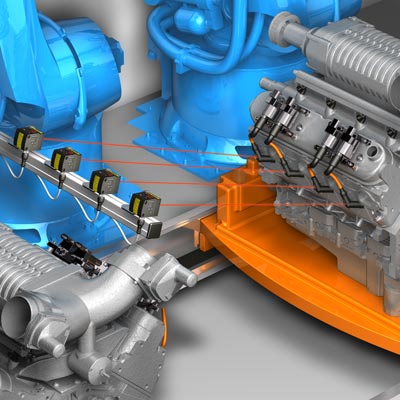

Presence control for spark plug connector in an engine block

Optical distance sensor

LAT45-10MIU-B5

SOLUTIONS

LABORATORY AUTOMATION

Laboratory automation enables, independent of the number of the samples, valid and fast analysis results. Distance sensors within analysis machines can ensure that samples are correctly prepared for further processes – reliable in their function and with high availability.SOLUTIONS

MOBILE EQUIPMENT

Mobile equipment has a broad range of application, both in agriculture and forestry and in materials handling. Optical sensors and ultrasonic sensors from di-soric can be used in a need-specific way for the regulation of distances and positioning tasks. The measurement of distances of the most diverse kinds objects is performed simply and reliably.

Checking screw tops on tubes

Optical distance sensor

LVHT52-500G3-B4

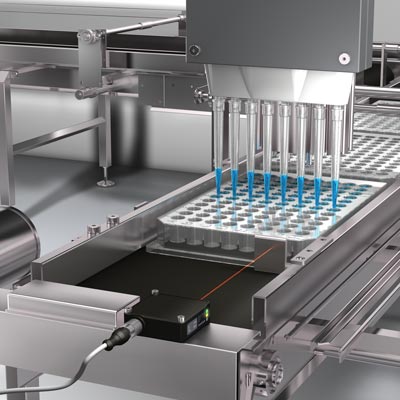

Linear positioning of pipettors

Optical distance sensor

LAT52-500IU-B5

Measurement of boom height on sprayers

Ultrasonic sensor

US 30 M 3000 IU-B4

Positioning of a lifting platform

Optical distance sensor

LAT45-10MIU-B5

SOLUTIONS

RUBBER AND PLASTICS

di-soric sensors are used in the processing of raw material and in the downstream processing and refinement of plastics. Distance measurement of the most diverse materials monitors fill levels and regulates various production processes.SOLUTIONS

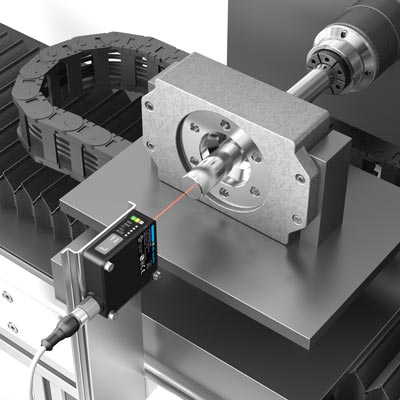

MACHINE TOOLS

A high degree of precision and measuring rate, coupled with absolute reliability are a must for sensors in modern machine tools. di-soric laser distance sensors also offer the necessary robustness. They detect distances and positions with a high degree of precision and enable high performance in the case of chipping, casting and reshaping production processes.Diameter control on a film extruder

Ultrasonic sensor

US 12 M 400 G3-B4

Checking granulate fill level

Optical distance sensor

LAT45-10MIU-B5

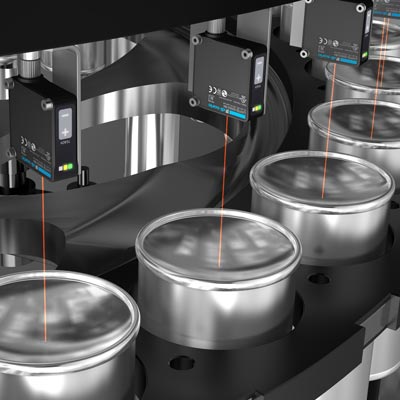

End position control in can production

Optical distance sensor

LVHT52-500G3-B5

Detection of weld seams

Optical distance sensor

LAT 61 K 50/20 IUPN

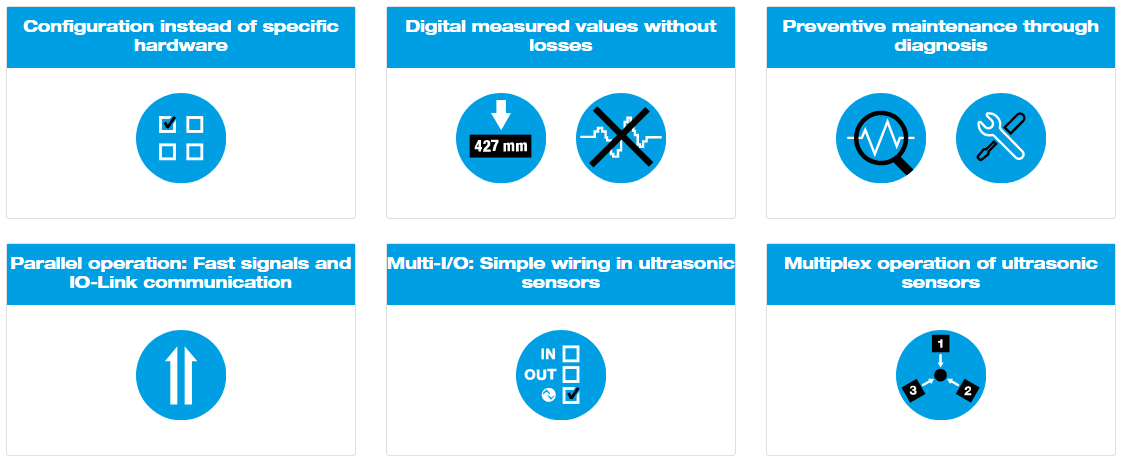

More flexible, more transparent, more efficient

Production processes with IO-Link

IO-Link is a worldwide communication standard according to IEC 61131-9. Sensors and actuators with an immense range of functions and capabilities become intelligent and active process devices in the field with IO-Link. Production processes thereby become more flexible, more transparent, more efficient and more cost-efficient. IO-Link transforms sensors into digital products and enables Industry 4.0 systems designs.