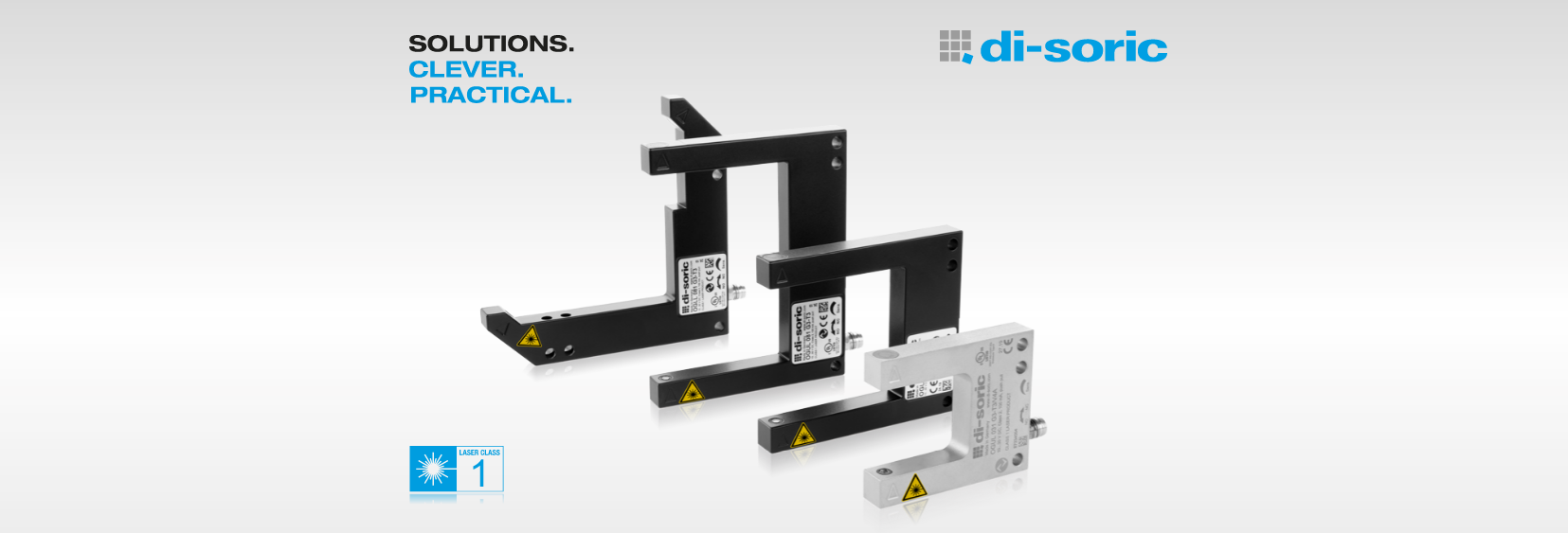

Çatal Sensörler OGUL / OGLL

MAXIMUM PRECISION:

LASER FORK AND ANGLED

LIGHT BARRIERS WITH IO-LINK

LASER FORK LIGHT BARRIERS OGUL LASER

ARE USED WHEN THE SMALLEST PARTS

MUST BE DETECTED.

The OGUL series available with fork openings of 30, 50, 80 and 120 mm is the best solution when the goal is process-reliable and fast detection of very small objects down to a size of just 0.03 mm.

With OGUL, the position and alignment of thin wires, drill bits or cannulae can effortlessly be defined down to a (reproducible) accuracy of 0.01 mm.

BENEFITS OF THE PRECISE OGUL LASERS / OGUL LASER STAINLESS STEEL:

Standard mode is the default – the High Resolution, Speed and Power modes can be selected via IO link

Detection of very small parts in assembly, handling and packaging technology, as well as quality control

OGUL APPLICATIONS

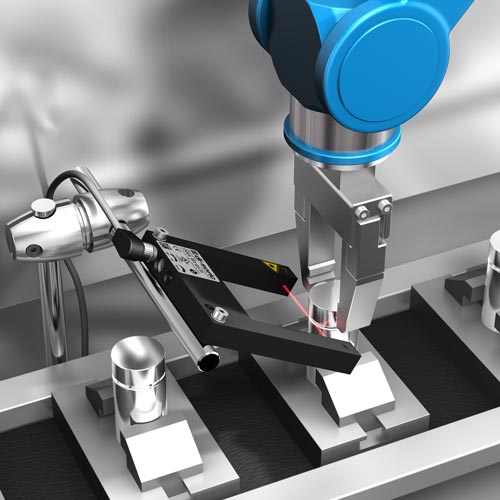

Position monitoring: groove present?

OGUL 051 G3-T3

The correct position of cylindrical components is verified by checking for the presence of a small groove. Our OGUL laser fork light barrier features a clearly visible laser beam and handles this task with functional reliability.

In the NC position of the potentiometer, the switching output is switched off if no groove is present, and the product can be rejected.

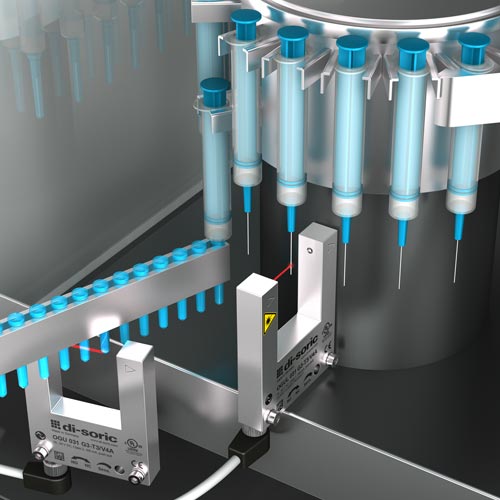

Cannulae monitoring

OGUL 031 G3-T3

A feeding unit transports disposable syringes in a hanging position to their final assembly station at a high speed. A rotary table is used to fit plastic caps on the syringes. Before this table, the needles pass through a laser fork light barrier from the OGUL series. The thin needle has to be detected as present before the system is allowed to put the cap on.

The challenge in this application: the cannula measures 0.3 mm, so the cycle times are short. Users in the clinical sector rely on the presence of a fully functional disposable syringe in every package.

THE ANGLED LIGHT BARRIERS OGLL LASER

DETECT RAPID-CYCLE OBJECTS WITH PROCESS RELIABILITY, DOWN TO A SIZE OF 0.03 MM.

The OGLL series is the best solution when the goal is process-reliable and fast detection of very small objects down to a size of just 0.03 mm. With OGLL laser angled light barriers the position and alignment of thin wires, drill bits or cannulae can effortlessly be defined down to a (reproducible) accuracy of 0.01 mm.

BENEFITS OF THE PRECISE LASER ANGLED

LIGHT BARRIERS OGLL:

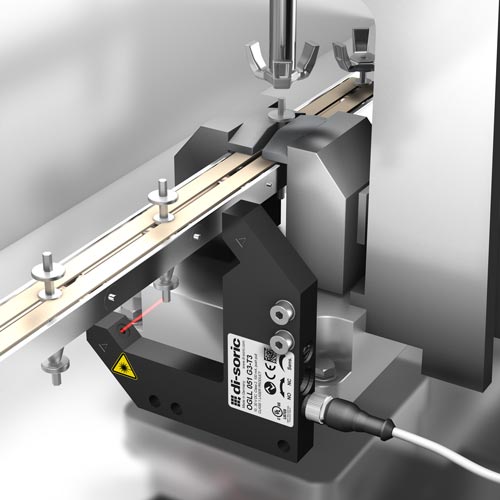

OGLL APPLICATION

Checking connector contacts OGLL 051 G3-T3

At a supply unit that feeds an assembly machine, a laser angled light barrier from the OGLL series is used in narrow installation spaces. It checks supplied components to see whether the very thin connector contacts are present.

The high resolution of the laser sensor guarantees that even extremely thin wires are detected with certainty. The easily visible laser light spot allows the sensor to be aligned and adjusted quickly and precisely.